Elektrik Mühəndisliyi və İnşaat aləmində, Doğru naqil növünün seçilməsi həm təhlükəsizlik, həm də səmərəlilik üçün çox vacibdir. İki dəfə istifadə olunan iki növ tel zirehli kabellər və çılpaq dirijorlardır. Hər birinin öz xüsusiyyətləri var, üstünlük, və tətbiqlər. This article SWA Cable delves into the differences between armored cables and bare conductors, helping you make informed decisions for your electrical projects.

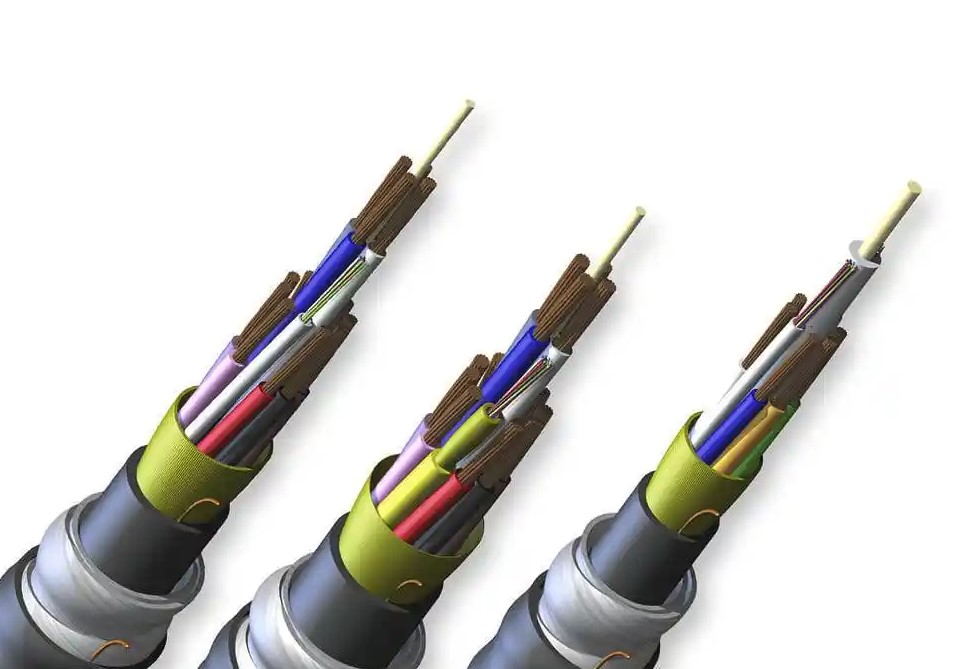

What Are Armored Cables?

Armored cables, also known as armored electrical cables, are a type of cable with a protective metal covering. This metal sheath can be made from various materials, including steel or aluminum, providing enhanced durability and protection against physical damage, moisture, and other environmental factors.

Construction of Armored Cables

- Dirijor: The core of an armored cable consists of one or more electrical conductors, typically made of copper or aluminum, which carry the electrical current.

- İzolyasiya: Each conductor is surrounded by an insulating material, usually made of plastic or rubber, to prevent electrical leakage and short circuits.

- Armoring: The insulated conductors are encased in a metal sheath, which provides mechanical protection and increases the cable’s resistance to external damage.

- Outer Jacket: An additional layer of plastic or rubber is often added over the armoring to provide further protection and environmental resistance.

Types of Armored Cables

- Steel-Wire Armored (Swa): Commonly used for underground installations and in harsh environments where mechanical protection is paramount.

- Aluminum-Wire Armored (AWA): Often used in situations where the weight of the cable is a concern, as aluminum is lighter than steel.

- Lead-Sheathed Cables: Used in environments with chemical exposure due to lead’s resistance to corrosion.

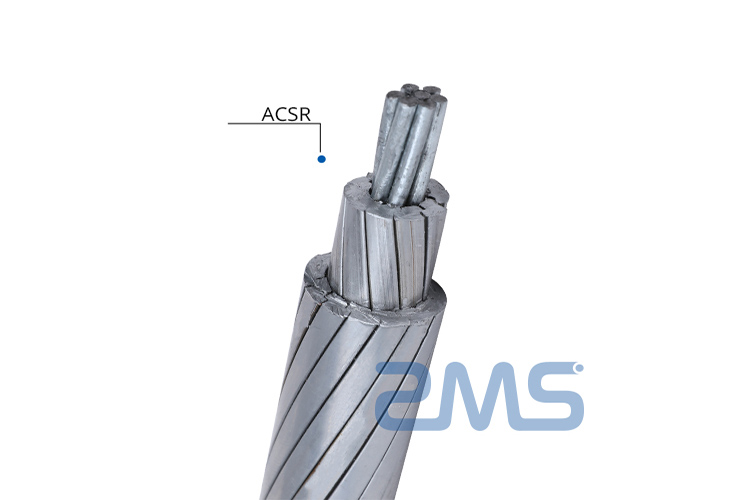

What Are Bare Conductors?

Bare conductors are wires without any insulation or protective covering. These conductors are usually made of aluminum, mismar, or alloys and are used primarily in overhead power lines and other outdoor applications where insulation is not necessary or would hinder performance.

Construction of Bare Conductors

- Material: Bare conductors are typically made of high-purity copper or aluminum, known for their excellent electrical conductivity.

- Stranding: To improve flexibility and mechanical strength, bare conductors are often stranded, meaning they are composed of multiple smaller wires twisted together.

Types of Bare Conductors

- Solid Conductors: Single, solid wire, used for specific applications where flexibility is not a primary concern.

- Stranded Conductors: Composed of multiple smaller wires twisted together, offering greater flexibility and strength.

- AAC (All Aluminum Conductor): Made entirely of aluminum, used mainly for short spans and low-stress environments.

- ACSR (Aluminum Conductor Steel Reinforced): Features a steel core for added strength, used in long-span transmission lines.

- AAAC (All Aluminum Alloy Conductor): Made from aluminum alloys, providing a good balance of strength and conductivity.

Key Differences Between Armored Cables and Bare Conductors

1. Protection and Durability

- Armored Cables: Offer superior protection against physical damage, moisture, chemicals, and environmental factors due to their metal sheath and outer jacket. They are ideal for underground installations, industrial environments, and areas prone to mechanical stress.

- Bare Conductors: Lack any form of insulation or protection, making them susceptible to physical damage and environmental factors. They are typically used in open-air environments where mechanical protection is less concerned.

2. Tətbiqlər

- Armored Cables: Widely used in industrial settings, underground installations, power distribution networks, and areas where enhanced protection is needed. They are also common in residential and commercial buildings for power and communication lines.

- Bare Conductors: Primarily used in overhead power lines, substation connections, and other outdoor applications where insulation is not required. They are also used in grounding and bonding applications.

3. Cost

- Armored Cables: Generally more expensive than bare conductors due to the additional materials and manufacturing processes involved in their construction. The cost includes the metal sheath, insulation, and outer jacket.

- Bare Conductors: Typically less expensive because they lack insulation and protective coverings, reducing material and manufacturing costs.

4. Installation

- Armored Cables: Installation can be more complex and time-consuming due to their added weight and rigidity. They may require special tools and techniques to ensure proper handling and protection during installation.

- Bare Conductors: Easier and faster to install, especially in overhead applications, due to their lighter weight and flexibility. They require fewer special tools and techniques.

5. Flexibility and Handling

- Armored Cables: Less flexible and more difficult to handle due to the metal sheath and outer jacket. They may require additional support and bending allowances during installation.

- Bare Conductors: More flexible and easier to handle, especially stranded conductors. Their lack of insulation and protective covering allows for greater maneuverability and ease of installation.

6. Electrical Performance

- Armored Cables: Provide consistent electrical performance with added protection against electrical interference, making them suitable for sensitive applications. The insulation also prevents electrical leakage and short circuits.

- Bare Conductors: Offer excellent electrical performance but are more susceptible to environmental factors and physical damage. They are often used in high-voltage applications where insulation is not critical.

Advantages of Armored Cables

- Enhanced Protection: The metal sheath and outer jacket provide superior protection against mechanical damage, moisture, chemicals, and environmental factors.

- Safety: Insulated conductors reduce the risk of electrical leakage, short circuits, and other hazards.

- Durability: The robust construction ensures a longer lifespan, even in harsh environments.

- Reduced Electrical Interference: The metal sheath can act as a shield against electromagnetic interference (EMI), improving signal quality in communication lines.

Disadvantages of Armored Cables

- Cost: Higher initial cost compared to bare conductors due to the additional materials and manufacturing processes.

- Weight and Rigidity: Heavier and less flexible, making installation more challenging and time-consuming.

- Special Handling: Requires special tools and techniques for proper installation and handling.

Advantages of Bare Conductors

- Cost-Effective: Lower initial cost due to the lack of insulation and protective coverings.

- Ease of Installation: Lighter weight and greater flexibility make installation faster and easier, especially in overhead applications.

- High Conductivity: Excellent electrical performance with minimal resistance.

Disadvantages of Bare Conductors

- Lack of Protection: Susceptible to physical damage, moisture, and environmental factors due to the absence of insulation and protective coverings.

- Safety Concerns: Increased risk of electrical hazards, such as short circuits and electrical leakage, in certain applications.

- Limited Applications: Primarily used in outdoor and overhead environments, with limited suitability for indoor or underground installations.

Choosing Between Armored Cables and Bare Conductors

When deciding between armored cables and bare conductors, several factors should be considered:

- Application: Determine the specific requirements of your project, including the environment, mechanical stress, and potential exposure to moisture and chemicals.

- Budget: Consider the initial cost and long-term maintenance expenses associated with each type of wiring.

- Installation: Evaluate the complexity and time required for installation and the availability of necessary tools and expertise.

- Safety: Assess the safety implications of each type of wiring, including the risk of electrical hazards and the need for additional protective measures.

Both armored cables and bare conductors have their unique advantages and disadvantages, making them suitable for different applications. Armored cables provide enhanced protection, durability, and safety, making them ideal for industrial, yeraltı, and harsh environments. Digər tərəfdən, bare conductors offer cost-effective, çevik, and easy-to-install solutions for overhead and outdoor applications.

By understanding the differences between these two types of wiring, you can make informed decisions that ensure your electrical projects’ safety, efficiency, and longevity. Whether you choose armored cables for their robust protection or bare conductors for their cost-effectiveness and ease of installation, selecting the right type of wiring is essential for achieving optimal performance and reliability in your electrical systems.