Wire Insulation — XLPE/PVC Insulation

ZMS cable suppliers have a huge sales volume and can produce a lot of wire insulation. And export to many countries and regions. The customers who received the goods have no negative comments. No matter what type of insulation cable you want, we can produce it for you. ZMS Cable’s main insulation wire divide into two categories. One is PVC cable and the other is XLPE cable insulation.

ZMS cable company adheres to the concept of honest management, and has been in good development since its establishment. The company has been committed to the improvement of cable quality and after-sales service after customers purchase.

Definition of Wire Insulation

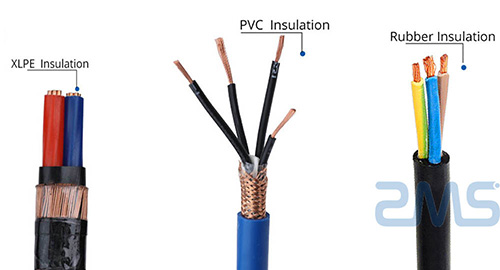

Power cable wire insulation refers to a cable wrapped with a non-conductive material on the outside of the conductor. Most of these materials are resins, plastics, silicone rubbers, synthetic compounds and so on. Insulation can prevent safety accidents such as leakage and short circuit caused by contact between the conductor and the outside world. Insulation wire include XLPE cable, PVC cable and rubber cable.

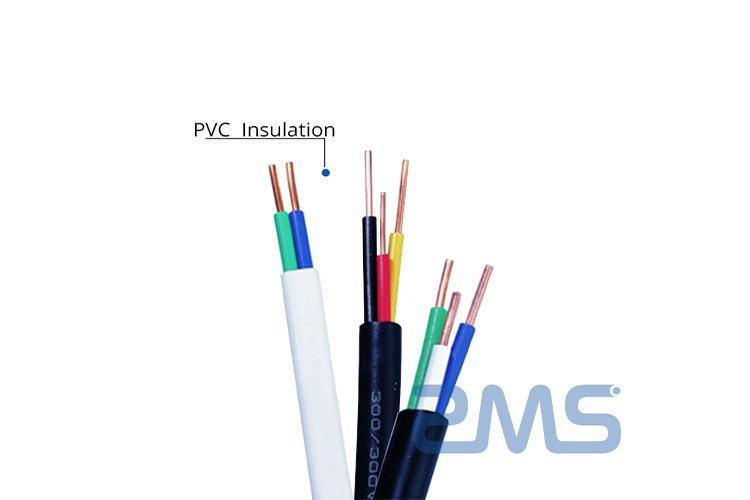

Types of Insulation Wire (PVC Insulation Cable)

The full name of PVC cable wire insulation is polyvinyl chloride insulated cable. PVC cable insulation refers to an insulated cable that uses PVC as an insulating material.

Formulation of PVC wire insulation.

Wires and cables used in different environments have different requirements. So the formula of PVC insulation is not static. And some adjustments can make appropriately according to the actual use.

Advantages of PVC Cable Wire Insulation Cable

First, PVC wire insulation has mature production and processing technology. The maturity of manufacturing technology has greatly reduced the manufacturing cost of PVC. And the quality is also higher.

Secondly, the flame retardant performance is good, and the PVC cable can easily meet the design requirements for use in the flame retardant grade.

Thirdly, wire insulation has high-temperature resistance, PVC cable can change the insulation performance by changing the PVC material formula, which makes PVC insulation wires also have diversification, which can be roughly divided into the following three types

No.1 ordinary type. The maximum operating temperature of the ordinary type is 105℃. Its main use area is the outer sheath. Ordinary cables are easy to shape and are relatively soft. Different hardness can be determined according to actual conditions.

No.2 semi-rigid. Abbreviated as SR-PVC, the maximum working temperature is 105℃, mainly used for core cables. Its hardness is higher than that of ordinary cables, and its mechanical strength and stability are also better. Viszont, its softness is not good and its application range is limited.

No3. Cross-linked PVC. The maximum working temperature of XLPE for short is still 105 °C. It is a new type of PVC material obtained through cross-linking. The molecular structure is more stable than before. While improving the mechanical strength of the insulation, the short-circuit temperature can reach 250 °C.

No4. PVC wire insulation have a wide range of uses, occupying a leading position in industries such as household appliances, instrumentation, lighting, and network communications.

Disadvantages of PVC Cable Wire Insulation

First of all, PVC cable contains a large amount of harmful toxin chlorine, which will release dense smoke when burned to make people suffocate, and also produce carcinogens and HCI gas which are very harmful to the environment.

Secondly, PVC wire insulation are not resistant to acid, alkali, hot oil and organic solvents, stb. PVC cables are prone to breakage and breakage in these environments.

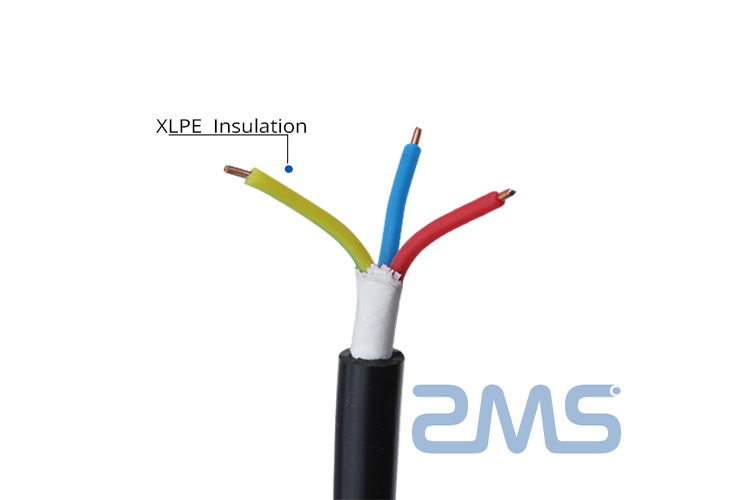

Definition of XLPE Cable

The full name of XLPE cable is cross-linked polyethylene wire insulation. It is a power cable that uses XLPE as an insulating material. XLPE cables use in the power supply grid widely.

XLPE cable has high-temperature resistance wire insulation performance. XLPE cable can work for several hours at a high temperature of 90 ℃, and the thermal life can reach 40 years.

Advantages of XLPE Wire Insulation Cable

Wire insulation performance. The XLPE cable has further upgraded the insulation performance of PE. And the electrical loss is not large and the influence of temperature is also reduced.

Mechanical properties. The internal molecular composition of PE is changed through cross-linking, so that all aspects of mechanical properties of XLPE such as bendability, abrasion resistance, and impact resistance have been improved. This makes up for the defect that PE is susceptible to environmental influences and cracks.

Corrosion resistance. XLPE has very good corrosion resistance and abrasion resistance, and has little harm to nature. By the way, ZMS product has the high quality. And obviously, ZMS cable company is very good. If you want to get a fresh price. Please inquiry us or send e-mail for us.

The Difference Between PVC and XLPE Wire Insulation Cables

First, the thermal life of XLPE cable is longer than that of PVC cables, 40 years for XLPE cables and 20 years for PVC cables.

Secondly, when the PVC cable burns, it will release a lot of dense smoke and toxic gas. And the XLPE cable will not produce halogen toxic gas when it burns.

Thirdly, XLPE cables can work continuously at a high temperature of 90 °C, while PVC cables can only work at a high temperature of 70 °C. Ráadásul, the maximum short-circuit temperature of the conductor is also different. It is 160 °C for PVC cables and 250 °C for XLPE cables.

About ZMS Cable

ZMS is an excellent Chinese cable manufacturing and wholesaling company. The company has numerous orders sold all over the world every year. Meanwhile, we will always follow up on the shipping status so that our customers can get the goods in the fastest time. Our quality is absolutely guaranteed. Our factory adopts fine management. Ráadásul, each worker is responsible for his work seriously. ZMS cable price also has a great advantage. Our production equipment is very advanced. Therefore, it can improve production efficiency and reduce the production cost for us in the production process. We look forward to your inquiry.