Perkenalan

As sustainability becomes a global priority, Industri di seluruh spektrum mengevaluasi kembali operasi mereka untuk selaras dengan prinsip -prinsip ekonomi sirkular. Industri kabel, a cornerstone of infrastructure development and energy transmission, has a critical role to play. This article explores the role of the cable industry in the circular economy, the challenges it faces, and the strategies to overcome them.

Understanding the Circular Economy

The circular economy is an economic model aimed at minimizing waste and maximizing resource use through recycling, reusing, and repurposing. For the cable industry, this means designing products that last longer, are easier to recycle, and minimize environmental impact during production and disposal.

Key Principles of the Circular Economy

1. Design for Durability: Ensuring cables have longer lifespans to reduce replacement frequency. Durability minimizes resource consumption and waste, directly contributing to sustainability.

2. Recycling and Reuse: Encouraging the recovery of valuable materials like copper, aluminum, and plastics from old cables. This not only reduces the demand for virgin materials but also conserves energy.

3. Eco-friendly Production: Using sustainable materials and energy-efficient manufacturing processes, the cable industry can significantly lower its carbon footprint while supporting circular economy principles.

The Cable Industry’s Role in the Circular Economy

Sustainable Materials

The cable industry is increasingly adopting sustainable materials. Misalnya, Smoke-Smoke Zero-Halogen (LSZH) cables are designed to reduce toxic emissions during a fire, contributing to a safer and more sustainable environment. Selain itu, bio-based insulations made from renewable sources are becoming more prevalent, aligning with the goals of the circular economy.

Recycling Initiatives

Cable recycling involves extracting valuable materials from used cables. Metals like copper and aluminum can be recycled without losing quality, making them ideal for a circular economy. Some companies have established take-back schemes to encourage recycling, ensuring cables are appropriately processed at the end of their lifecycle.

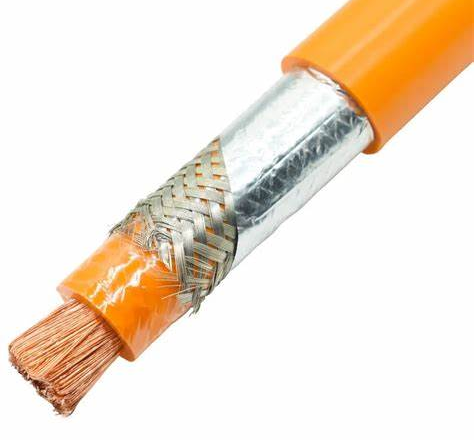

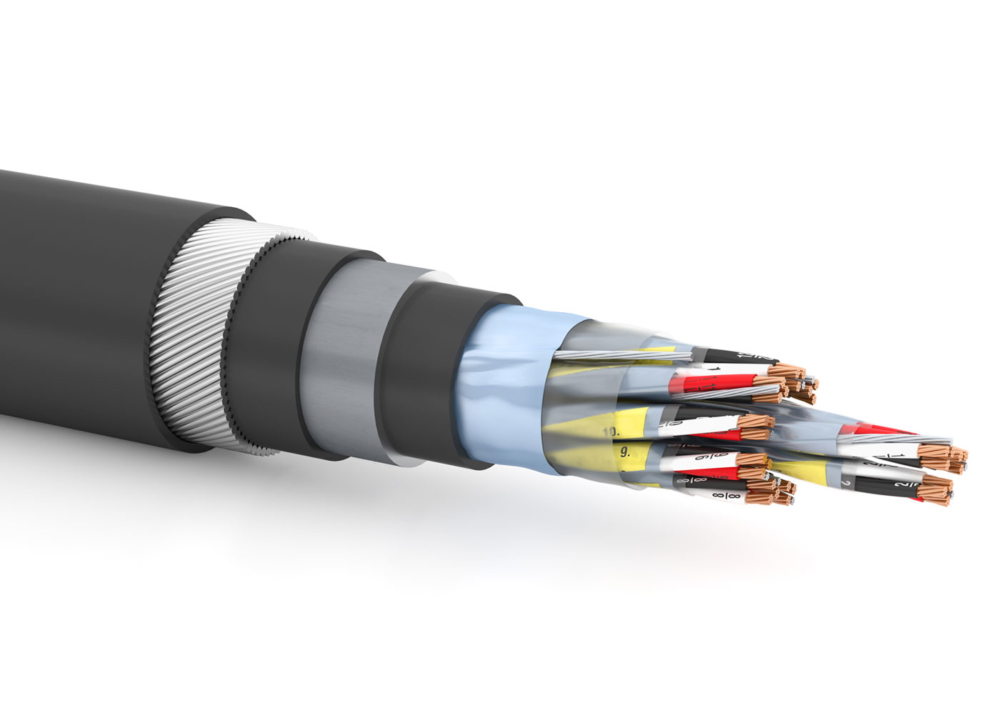

Innovations in Design

Advanced cable designs now incorporate modular components that are easier to disassemble and recycle. This approach reduces waste and simplifies the recycling process. Manufacturers are also incorporating designs that allow cables to be reused in secondary applications, extending their lifecycle.

Emerging Trends in the Cable Industry and Circular Economy

Kabel pintar dan integrasi IoT

Smart cables embedded with sensors contribute to sustainability by enhancing efficiency and reducing waste during operations. These cables can monitor performance in real-time, alerting users to potential issues before they result in failure or waste.

Bio-based Materials

The industry is exploring the use of biodegradable or bio-based materials, reducing reliance on traditional plastics. These materials decompose naturally, minimizing environmental impact when cables reach the end of their useful life.

Second-life Applications

Recycled cable materials are finding innovative second-life applications in other industries. Sebagai contoh, recovered copper and aluminum are used in the production of new electrical components, while plastics are repurposed into construction materials.

Challenges Facing the Cable Industry

Technical Challenges

1. Material Complexity: Many cables are composed of multiple materials, making recycling a technical challenge. Misalnya, separating plastic insulation from metallic cores requires specialized machinery and processes.

2. Recycling Infrastructure: Limited infrastructure for efficient cable recycling remains a significant barrier. Many regions lack the facilities to process cables, leading to valuable materials being discarded.

Economic Challenges

1. High Recycling Costs: The cost of recycling can sometimes outweigh the benefits, especially for low-value materials. This economic imbalance discourages investment in recycling initiatives.

2. Market Demand: Limited demand for recycled materials can discourage investment in recycling technologies. Manufacturers often prefer virgin materials due to their consistent quality and lower costs.

Regulatory and Awareness Challenges

1. Lack of Standardization: Inconsistent regulations across regions make it challenging for global companies to adopt uniform recycling practices. This lack of standardization hinders the development of efficient, large-scale recycling programs.

2. Consumer Awareness: Many consumers are unaware of recycling options for cables, resulting in a significant portion of cables ending up in landfills. Public education is essential to drive participation in recycling initiatives.

Strategies for Overcoming Challenges

Advancing Technology

Investing in advanced recycling technologies can address the complexity of material separation and reduce costs. Sebagai contoh, automated sorting systems and chemical recycling methods can significantly improve efficiency. Companies can also explore new technologies like pyrolysis for processing mixed materials.

Policy and Regulation

Governments can play a pivotal role by introducing incentives for recycling and creating standardized guidelines for cable manufacturers. Policies that mandate the use of recycled materials in production can stimulate demand and encourage sustainable practices.

Industry Collaboration

Collaboration among industry stakeholders can lead to shared recycling facilities and resources, reducing costs and improving efficiency. Joint ventures and partnerships can drive innovation and accelerate the adoption of circular economy practices.

Consumer Education

Raising awareness about cable recycling options can drive higher participation rates. Companies can implement campaigns to educate consumers about the benefits of recycling cables. This can include labeling cables with recycling instructions and offering convenient drop-off locations.

Circular Economy in Action

Successful Recycling Programs

Highlight examples of regions or companies that have implemented effective cable recycling programs. Misalnya, countries like Sweden have established robust recycling systems, achieving high rates of material recovery.

Lessons Learned

Discuss how these case studies address specific challenges and provide a model for other stakeholders to follow. Emphasize the importance of collaboration, inovasi, and regulatory support in achieving success.

Environmental and Economic Benefits

Quantifying Environmental Impact

Illustrate the reduction in CO2 emissions and waste achieved through cable recycling. Provide data-driven examples to highlight the environmental benefits, such as energy savings from using recycled copper compared to mining new materials.

Economic Opportunities

Explore the cost savings for manufacturers and the creation of new markets for recycled materials. Misalnya, selling recovered metals and plastics can create additional revenue streams, offsetting recycling costs.

Consumer and Industry Stakeholder Roles

Consumer Responsibility

Encourage proper disposal of cables to facilitate recycling efforts. Consumers play a critical role in ensuring that cables are directed to appropriate recycling facilities rather than discarded in landfills.

Manufacturer Accountability

Promote the development of eco-friendly designs and participation in take-back programs. Manufacturers should prioritize sustainability in their operations, from material selection to end-of-life product management.

Cross-sector Collaboration

Highlight partnerships between governments, recycling centers, and manufacturers as critical to advancing the circular economy. Collaborative efforts can streamline processes, reduce costs, and improve outcomes.

Kabel ZMS: A Leader in Sustainable Practices

As a leading cable manufacturer, ZMS Cables is at the forefront of sustainable practices. The company offers customizable cables designed for longevity and recyclability. By using eco-friendly materials and adopting innovative recycling methods, Kabel ZMS exemplifies how businesses can thrive while supporting a circular economy.

Future Outlook for the Cable Industry in a Circular Economy

Upcoming Innovations

Predict advancements in materials and recycling technologies likely to impact the industry. Sebagai contoh, the development of self-healing cables could significantly extend product lifespans, reducing waste.

Regulatory Trends

Discuss expected policy developments that will influence the industry’s transition to sustainability. Global agreements and stricter regulations may drive faster adoption of circular economy practices.

FAQs on the Circular Economy and Cable Recycling

Common Questions Answered

1. What is the lifespan of an average cable?

Most cables have a lifespan of 20-30 bertahun-tahun, depending on their application and quality.

2. Can all cables be recycled?

While most cables can be recycled, the complexity of some materials can make the process challenging.

3. How does cable recycling contribute to sustainability?

Recycling reduces the need for raw material extraction, conserves energy, and minimizes waste.

Providing clear answers can increase consumer awareness and support recycling efforts.

Kesimpulan

The cable industry’s transition to a circular economy is essential for achieving global sustainability goals. While challenges remain, advancements in technology, regulatory support, and increased awareness can pave the way for a more sustainable future. By adopting circular economy principles, the cable industry can not only reduce its environmental footprint but also unlock new economic opportunities.