Kolvetnisþolnir kaplar eru nauðsynlegir í umhverfi sem verða fyrir ýmsum kolvetnisefnum eins og olíum, eldsneyti, og leysiefni. Hannað til að standast ætandi áhrif, þessar snúrur tryggja áreiðanleika og öryggi, sérstaklega í iðnaði þar sem útsetning fyrir kolvetni er tíð. Þessi grein mun kanna einstaka eiginleika kolvetnisþolinna strengja, lykilforrit þeirra, og hvers vegna þeir skipta sköpum í greinum sem fást við olíu- og efnaváhrif.

Skilningur á kolvetnisþoli í snúrum

Kolvetnisþol í snúrum vísar til getu til að standast niðurbrot þegar þau verða fyrir kolvetni. Kolvetni, lífræn efnasambönd sem samanstanda aðallega af vetni og kolefnisatómum, finnast í jarðolíu, jarðgas, og ýmis iðnaðarefni. Með tímanum, þessi efnasambönd geta rýrnað venjuleg kapalefni, sem leiðir til taps á sveigjanleika, sprunga, eða algjör bilun.

Til að berjast gegn þessum áhrifum, kolvetnisþolnir kaplar eru framleiddir með sérstaklega samsett efni, svo sem pólýetýlen (PE), flúorfjölliða (eins og Teflon), og pólýúretan (PUR), hannað til að standast innsog kolvetnis. Þessi efni veita ekki aðeins viðnám gegn olíum og eldsneyti heldur tryggja einnig að kapallinn haldi rafmagns- og vélrænni eiginleikum sínum við langvarandi útsetningu.

Helstu eiginleikar kolvetnisþolinna kapla

Kolvetnisþolnir kaplar eru hannaðir til að þola krefjandi aðstæður sem venjulegar kaplar ráða ekki við. Hér eru nokkur af einkennandi eiginleikum þeirra:

- Hár efnaþol

Þessir kaplar eru efnafræðilega stöðugir þegar þeir verða fyrir ýmsum efnum sem byggjast á kolvetni, dregur úr hættu á niðurbroti eða veðrun með tímanum. - Ending og langlífi

Efnin sem notuð eru í kolvetnisþolna strengi eru þekkt fyrir endingu. Þeir þola bæði líkamlegt og efnafræðilegt slit, sem gerir þau tilvalin fyrir langtíma notkun. - Hitastöðugleiki

Í umhverfi þar sem hitastig sveiflast, kolvetnisþolnir strengir haldast stöðugir. Þetta skiptir sköpum í atvinnugreinum eins og olíuvinnslu, þar sem hiti getur verið mikill.

4. Eldviðnám

Sumir kolvetnisþolnir kaplar eru einnig logavarnarefni, bæta við viðbótarlagi af öryggi, sérstaklega í umhverfi þar sem hætta er á eldi.

5. Sveigjanleiki

Þrátt fyrir hrikalegt eðli þeirra, þessar snúrur viðhalda sveigjanleika, sem gerir þeim kleift að setja upp í þröngum rýmum eða yfir flókið skipulag iðnaðarvéla.

Framleiðslustaðlar og vottun

Til að tryggja gæði og öryggi, kolvetnisþolnir kaplar verða að vera í samræmi við iðnaðarstaðla og vottorð. Þar á meðal eru:

- IEC 60079-14 fyrir sprengiefni

- ISO 14572 fyrir kapalþol gegn efnum og eldsneyti

- UL staðlar, sem fela í sér sérstakar kröfur um strengi sem verða fyrir olíu og kolvetni

Þessir staðlar hjálpa til við að staðfesta áreiðanleika og hæfi kapalsins fyrir krefjandi umhverfi.

Notkun kolvetnisþolinna kapla

Kolvetnisþolnir strengir gegna mikilvægu hlutverki í iðnaði sem starfar í umhverfi sem verður fyrir olíu, gasi, og önnur efni sem byggjast á kolvetni. Hér eru nokkur af helstu forritunum:

Olíu- og gasiðnaður

The olíu og gasi geiri reiðir sig mjög á kolvetnisþolna strengi fyrir borpalla, hreinsunarstöðvar, og dreifikerfi. Þeir eru notaðir til að stjórna og knýja vélar, auðvelda samskiptakerfi, og stuðningseftirlitsbúnaði. Þessir kaplar tryggja hnökralausa starfsemi með því að draga úr hættu á bilun í kapal, sem getur haft í för með sér kostnaðarsaman stöðvunartíma.

Efnaframleiðsla

Efnaverksmiðjur fást við ýmis kolvetni í framleiðsluferlum sínum. Kolvetnisþolnir kaplar hjálpa til við að tryggja öruggar og áreiðanlegar tengingar milli véla, veita nauðsynlega vörn gegn ætandi umhverfi.

Umsóknir í sjó og á sjó

Úthafspallar og skip verða fyrir stöðugri útsetningu fyrir kolvetni vegna nálægðar þeirra við olíuvinnslustöðvar. Kolvetnisþolnir kaplar sem notaðir eru í sjávarumhverfi styðja lýsingu, orkudreifingu, og gagnasamskiptakerfi nauðsynleg fyrir öruggan og skilvirkan rekstur.

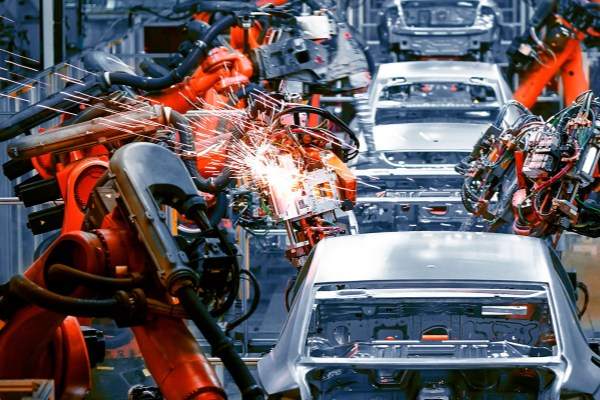

Bílaiðnaður

Í bílaframleiðslu og viðgerðaraðstöðu, kolvetnisþolnir kaplar eru mikilvægir. Þau eru notuð í forritum eins og eldsneytiskerfi, smurningarferli, og orkudreifingu innan ökutækja, tryggja öryggi og endingu á svæðum sem verða fyrir eldsneyti.

Námuvinnsla

Í námum er oft búnaður sem verður fyrir kolvetni frá eldsneytis- og smurkerfum. Kolvetnisþolnir kaplar veita áreiðanlegar afl- og samskiptalausnir við þessar erfiðu aðstæður, lágmarka hættu á bilun í búnaði.

Iðnaðar- og framleiðsluaðstaða

Margar iðnaðarstillingar nota kolvetnisþolna kapla fyrir vélar sem krefjast tíðar olíu og smurningar. Kaplarnir tryggja stöðuga notkun búnaðar með því að standast olíuáhrif, sem annars myndi skerða frammistöðu staðlaðra kapla.

Járnbrautir og almenningssamgöngur

Járnbrautaiðnaðurinn nýtur einnig góðs af kolvetnisþolnum strengjum, sérstaklega á svæðum eins og bensínstöðvum, viðhaldsmiðstöðvar, og lestarsmíði. Þessar snúrur styðja rafkerfi, gagnaflutningur, og aflgjafar í umhverfi þar sem útsetning fyrir olíu og eldsneyti er algeng.

Að velja rétta kolvetnisþolna kapalinn

Val á viðeigandi kolvetnisþolnum streng felur í sér að meta þætti eins og umhverfisaðstæður, kapalefni, og spennukröfur. Hér eru nokkur skref til að hjálpa við að velja rétta snúru:

- Metið útsetningu fyrir kolvetni

Ákvarða tegund og styrk kolvetnis í umhverfinu, þar sem sum efni henta betur fyrir ákveðin kolvetni. - Íhugaðu hitaþol

Hitaþol er nauðsynlegt ef kapallinn verður notaður í umhverfi með miklum eða sveiflukenndum hita. - Athugaðu fyrir vottorð

Leitaðu að snúrum sem uppfylla viðeigandi vottorð og staðla iðnaðarins, tryggja hæfi kapalsins fyrir fyrirhugað umhverfi. - Meta vélrænar kröfur

Veldu snúrur með viðeigandi vélrænni eiginleika, eins og sveigjanleika, togstyrk, og slitþol, eftir uppsetningarþörfum.

Uppsetning og viðhald kolvetnisþolinna strengja

Rétt uppsetning og reglulegt viðhald skipta sköpum til að hámarka endingu og skilvirkni kolvetnisþolinna strengja. Sumar bestu starfsvenjur eru ma:

- Rétt leiðsla kapalsins: Gakktu úr skugga um að snúrur séu lagðar til að forðast óþarfa beygju eða streitu.

- Venjulegar skoðanir: Athugaðu hvort snúrur séu slitnar eða niðurbrotnar, þar sem snemmgreining getur komið í veg fyrir stærri vandamál.

- Áætluð skipti: Fer eftir váhrifum og ástandi kapals, íhuga áætluð skipti til að forðast óvæntar bilanir.

Kolvetnisþolnir strengir eru ómissandi í geirum þar sem olíur verða fyrir áhrifum, eldsneyti, og efni er óumflýjanlegt. Hæfni þeirra til að standast ætandi áhrif kolvetnis gerir það að verkum að þeir eru ákjósanlegir kostir fyrir olíu og gas, efna, bifreiða, og sjávariðnaði, meðal annarra. Með því að skilja umsóknir þeirra, staðla, og viðhaldsþörf, fyrirtæki geta tryggt örugga og áreiðanlega starfsemi í kolvetnisríku umhverfi.