Importante! O que você precisa saber sobre a função da blindagem em cabos de controle

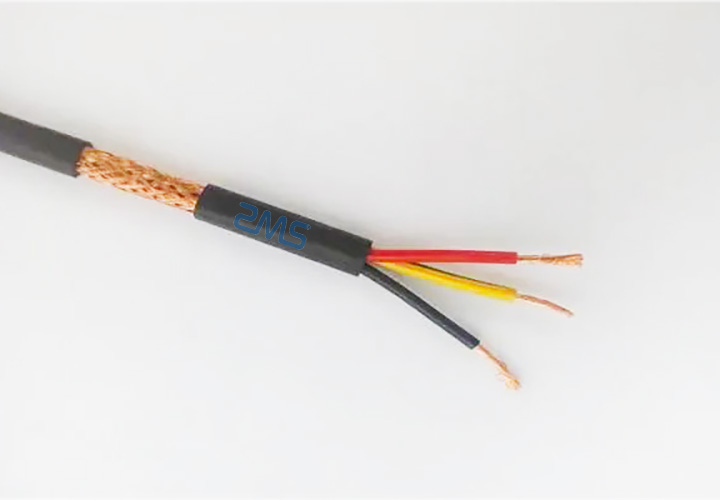

UMA cabo de controle blindado é geralmente usado como linha de conexão de instrumentos elétricos.

É adequado para a linha de conexão de instrumentos elétricos com tensão nominal CA de 450/750 V e inferior e a linha de transmissão do sistema de controle automático.

Possui excelentes propriedades, como resistência ao óleo, resistência à água, resistência ao desgaste, resistência a ácidos e álcalis, resistência a vários gases corrosivos, resistência ao envelhecimento, e não combustibilidade.

UMA cabo de controle blindado is a cable with a layer of mesh copper or metal wire woven around one or more wires. This layer of mesh metal wire can prevent lightning strikes and external signals cannot interfere with it.

The shield also provides some leakage protection. If the cable is damaged during use and leaks, the shield can direct the leakage current to the ground wire, providing some safety protection.

The role of shielding and grounding wire of shielded control cable is that the shielding layer is divided into internal shielding and external shielding.

They are both to make good contact between the cable conductor and insulation layer, and between the cable insulation layer and the inner protective layer, to eliminate the increase of surface electric field strength caused by the unsmooth surface of the conductor and the inner protective layer.

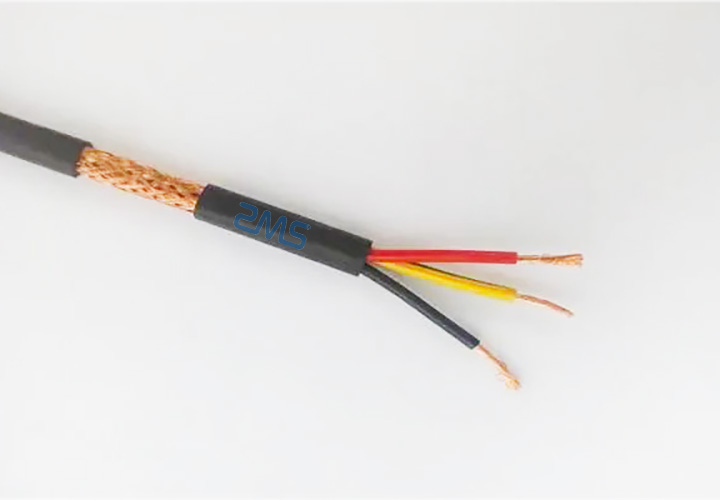

Product characteristics of shielded control cables.

(1) Allowable bending radius of the cable: the minimum bending radius of a non-armored cable is 6 times the outer diameter of the cable. Fluoroplastic insulated and sheathed cables should be at least 8 vezes o diâmetro externo do cabo. Copper tape shielded or steel tape armored cable should be at least 12 vezes o diâmetro externo do cabo.

(2) Maximum operating temperature: polytetrafluoroethylene propylene (F46) insulation should not exceed 200 ℃. Soluble polytetrafluoroethylene (PFA) insulation should not exceed 260 ℃.

(3) Minimum ambient temperature. PVC sheath: fixed laying -40℃, non-fixed laying -15℃. Fluorine plastic and silicone rubber sheath: fixed laying -60℃, non-fixed laying -20℃. Cable installation and laying temperature shall not be lower than 0℃ (fluoroplastic, silicone rubber and nitrile sheathed cable shall not be lower than -25℃).

Recent Posts

De cobre a fibra: A evolução do cabo

Introdução: o "Lifeline of Civilization" Across Time and Space In 1858, after five heartbreaking failures,…

Como entender rapidamente qual é o cabo trifásico? Favorito aqui!

In the world of industrial and commercial power distribution, three-phase cables play a critical role…

Tempestades e inundações! Como os cabos impermeáveis protegem a energia?

Introduction In recent years, heavy rainfall and flooding have become increasingly frequent worldwide, causing severe…

O papel e os desafios da indústria de cabos na economia circular

Introduction As sustainability becomes a global priority, industries across the spectrum are reevaluating their operations…

Como a indústria de cabos pode enfrentar o desafio da cadeia de suprimentos global?

The global supply chain is an intricate and essential network that connects manufacturers, distributors, retailers,…

O impacto das energias renováveis na demanda por cabos

Introduction The global shift toward renewable energy has become a cornerstone of efforts to combat…