Factors Affecting the Insulation Resistance of Wire and Cable Products

The insulation resistance of wire and cable products mainly measures the volume resistance of the cable insulation layer, the surface resistance cannot be measured, and more factors affect the value of cable insulation resistance. In practical application, there are four main factors on the insulation resistance coefficient.

1. Temperature influence:: As the temperature increases, the insulation resistance decreases due to the increase in thermal movement and the increase in ion generation and migration. Under the action of voltage, the conduction current formed by ion movement increases, so the insulation resistance decreases. Theory and practice show that the insulation resistance coefficient decreases exponentially with the increase in temperature, while the conductivity increases exponentially with the increase in temperature.

2. Electric field strength effect: when in the low range, the electric field strength so that the ion mobility increases with the electric field strength, ion current and electric field strength obey Ohm’s law. When the electric field strength is higher, the ion mobility increases with the electric field strength, the trend gradually changed from a linear relationship to an exponential relationship, when close to breakdown will have numerous electron migration. At this time, the insulation resistance factor is greatly reduced.

3. Humidity effects: due to the small electrical conductivity and the size of the water molecules are much smaller than the polymer molecules. Under the thermal effect of polymer macromolecules and the relative motion of the chain links, water molecules easily penetrate the polymer. To make the polymer conductive ions increase, insulation resistance decreases.

4. Material purity impact: the material is mixed with impurities, increasing the conductive particles in the material so that the insulation resistance decreases. Therefore, the size of the insulation resistance of rubber and plastic materials will reflect the purity of the material, to verify whether it meets the standard provisions. In the production process of wire and cable, not strictly comply with the process operating procedures, mixed with impurities, material moisture blistering, insulation part of the core or outside diameter size less than the standard provisions, cracks in the insulation layer or insulation scratches, etc., will make the insulation resistance of the product is reduced. Therefore, it is necessary to check the insulation resistance during operation to check whether there are problems. During the use of wire and cable, measuring the change of insulation resistance can also check the damage to insulation and prevent accidents from occurring.

Recent Posts

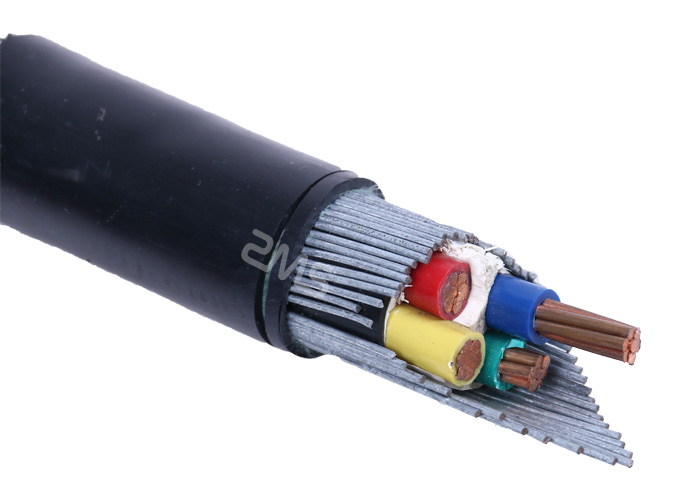

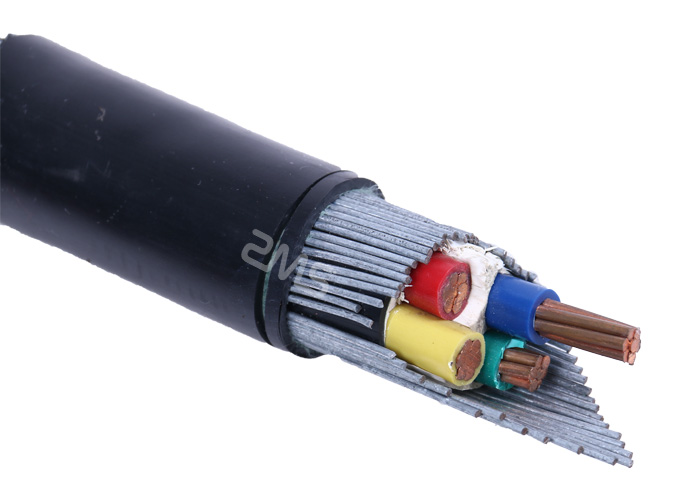

How to quickly understand what three-phase cable is? Favorite here!

In the world of industrial and commercial power distribution, three-phase cables play a critical role…

Storms and Floods! How Waterproof Cables Protect Power?

Introduction In recent years, heavy rainfall and flooding have become increasingly frequent worldwide, causing severe…

Cable Industry’s Role and Challenges in the Circular Economy

Introduction As sustainability becomes a global priority, industries across the spectrum are reevaluating their operations…

How Can the Cable Industry Meet Global Supply Chain Challenge?

The global supply chain is an intricate and essential network that connects manufacturers, distributors, retailers,…

The Impact of Renewable Energy on Cable Demand

Introduction The global shift toward renewable energy has become a cornerstone of efforts to combat…

Global Cable Market Trend Forecast 2025

The global cable market is integral to a wide array of industries, including energy, telecommunications,…