Three-core cable helps connect devices and machines to the mains.

The size of the 3-core cables you choose to use and the way you design your circuit can also affect your project.

Because of differences in applications and variations in project specifications.

Additionally, high-voltage applications often require high-quality cables, known as steel wire armor (SWA), and their applicable standards and specifications.

Therefore, you must be familiar with the 3-core armored cable colors, and what the conductors of each color are for.

In this post, we will discuss all of these issues in more detail.

What Is Three-core Cable?

It is important to know the type of wire or cable you will use.

No matter what electrical application you plan to work in.

A very popular choice for various purposes is the 3-core cable.

These cables contain three separate cores for three different purposes of transmitting electricity.

For example, if you choose to use a 1.5mm 3-core flex cable, there will be three separate wires inside the main cable jacket.

One of the wires is for powering, the other is for neutral wires, and the third wire in a 3-core cable is for ground (or ground) applications.

It may be helpful to review the above information from the perspective of other types of wires.

Unlike 3-core cables, 2-core cables have one less conductor. Its assembly consists of only two cores.

So, while a 10mm 3-core armored cable has a live, neutral, and ground (or ground) wire, the corresponding 2-core version of the same cable has no ground conductor. It only has live and neutral conductors.

What Is the Three-core Ground Wire Used for?

They are typically used in applications such as 2-way lighting for residential use, as well as in other applications. Such as central heating systems and wiring of equipment.

Depending on how the electrician designs the circuit for the 2-way lighting.

The 3-core and ground cables may have neutral or live applications.

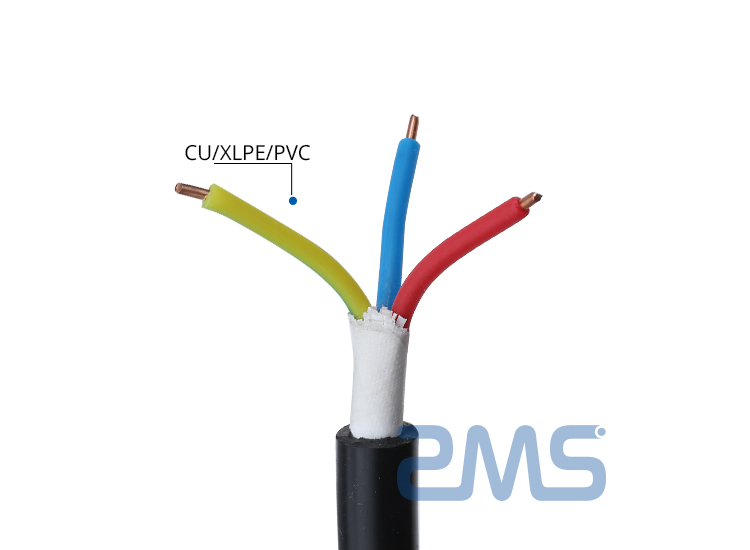

Generally, a three-core cable refers to a wire with three separate copper cores, each within its own protective jacket.

However, for the 3-core ground wire, a fourth conductor is inserted during the manufacturing process.

For example, a typical 3-core flex cable will have the usual 3-cores, including live, neutral, and ground, but will also have another conductor—a fourth.

This extra core is usually bare copper for grounding purposes.

In the above example , if we were using a 3-core flex cable with an extra bare copper conductor, the fourth conductor would have to be inserted into the green/yellow coded sleeve (ground) during installation.

Three-core Armored Cable for Electrical Applications

Core armored cable is also commonly known as three-core steel wire armored (SWA) cable.

For example, you might see a specification that says armoured cable 16mm 3 cores, BS546/BS6724.

This means that the cable meets the requirements of those specific UK cable manufacturing and testing standards.

Three core armored cables are known as power and auxiliary control cables.

Also known as 3-core power cables, these cables are wear-resistant cables and are used in applications where the cable may be damaged or where there is a danger of UV exposure.

The usual 3-core steel wire armoured cable (SWA) is ideal for external electrical applications.

Since such applications often have to withstand the forces of nature, SWA Outdoor 3-core cables have an additional outer sheath (usually wire mesh)

It provides greater mechanical protection to the inner core of such 3-core cables.

What Is the Three-core Cable Used for?

As mentioned earlier, a three-conductor cable is a cable that contains three conductors during the cable manufacturing process.

Each type of cable serves a different purpose, and we do not recommend for specific-purpose applications.

For example, if your ideal is a 1mm 3-core cable, it may not be the best practice to switch and use a thicker or thinner cable.

Typically, 3-core cable is usually the cable of choice for Class I connections to equipment.

This is because such devices (or related applications) need to provide a connection to Earth.

Two-core Cables vs Three-core Cables

Using 2-core wire instead of 3-core cable in these applications may affect the installation. Failure to ground may expose the user to electric shock.

Electricians can use the 2-core version of the cable instead of the 3-core cable in cases where grounding is not required.

For example, in an application involving a Class II equipment item, an engineer or electrician might use a 2-conductor braided cable instead of a 3-core braided cable.

The reason for this usage is because Class II equipment generally does not require a ground connection.

To sum up, the cables often depend on whether the equipment or appliance needs to be grounded.

According to the electrical code, the enclosure of a Class I appliance must be grounded.

For this, use a 3-core power cord. On the other hand, using a 2-conductor cable is safe for Class II applications.

In applications where there is a greater risk of electric shock if the live wire contacts the body of the equipment or appliance, a 3-core grounded cable is recommended.

For example, if the body is made of a non-conductive material, such as rubber, plastic, glass, or ceramic, it may not be necessary to use a 3-core cable.

However, it may be safe to choose an outdoor 3-core cable over an externally conductive 2-conductor wire such as metal, steel, iron, or copper.

You can use 2-conductor cable for non-conductive applications, but you must use 3-core cable for bulb sockets, lamp posts, and any other use cases where there is a high risk of electric shock.

Typically, 3-core steel wire armoured cables (SWA) are used to transmit power underground, from a power generation source to a residential or commercial location.

You can also see other armored products, such as 3-core 4mm armored cables, used with catenary wires in overhead power transmission applications.

Often, common electrical applications, such as power cords for lighting switches or appliances, can use flexible wires such as 3-core flex cables.

This is because their use enables cables to bend and twist without risk of breaking or splitting.

The Colors of 3-core Cables

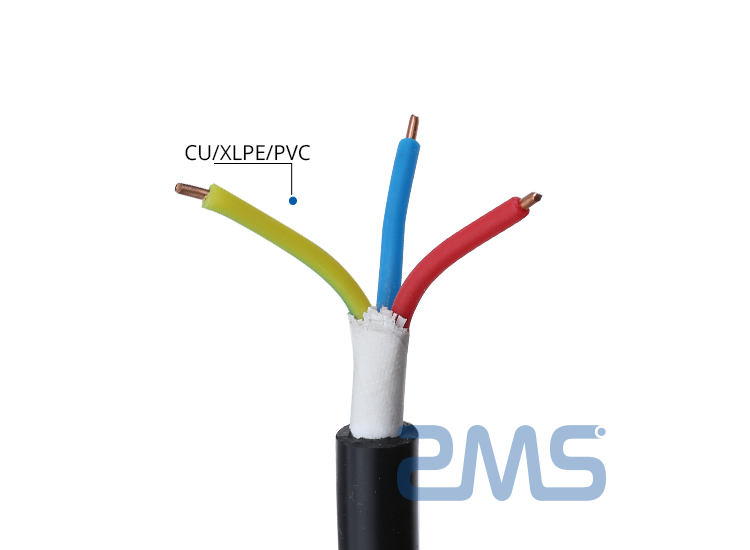

Both 2-conductor and 3-core cables have specific color requirements.

In March 2004, British Standard BS 7671 dealing with electrical installations made some changes to 2- and 3-core colours in the UK.

Changes to these standards took effect on April 1, 2004.

For example, before April 1st, you would see cable manufacturers selling 25mm 3-core armored cables in different colors, but after the new standard goes into effect, it’s illegal (since April 1, 2006) to sell or Use cables with older color schemes.

Until March 2004, the color standard of 3-core ground wire was blue, yellow, red, with ground wire.

However, after March 2004, the new 3-core cable colors are gray, black and brown as well as earth colors.

These color standards don’t go into effect overnight – there is a 2-year overlap (grace period) before the transition.

During this time, retailers sold 2- and 3-core armored cables, as well as other types of three-conductor products, both old and new coloring systems.

Why Did This Coloring Standard Change?

It is changed mainly to keep the cable colors in line with the rest countries of the EU.

Uniform colour codes are now in effect in all European countries as well as in the UK.

Under the new system, if your application requires a product such as 3-core flat cable, it will only sell the colour codes for the entire continent in the new system.