In modern power transmission systems, cables play a crucial role as the “veins” of the electrical grid. The quality and performance of cables directly impact the efficiency and safety of power transmission. AAC cables, or All Aluminum Conductors, have become essential in the energy industry due to their remarkable characteristics and wide range of applications. This article provides an in-depth analysis of AAC cables, covering their definition, characteristics, applications, advantages, and future trends.

What is an AAC Cable?

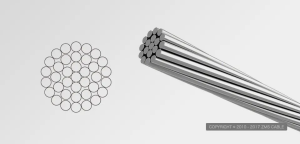

An AAC (All Aluminum Conductor) cable is a type of cable made up of several strands of aluminum twisted together. Unlike other cables, it does not contain a steel core, making it light and flexible. The aluminum used as the main conductor provides excellent conductivity and corrosion resistance, making AAC cables particularly suitable for short-distance power transmission scenarios.

AAC cables are used predominantly in overhead power lines and distribution networks. Their lightweight structure allows them to be installed in locations where other cables may not be viable, such as densely populated urban environments or areas with difficult terrain.

Materials and Standards for AAC Cables

Material Selection

Aluminum is the primary material used in AAC cables. In addition to its conductivity properties, aluminum is relatively low-cost, making it an ideal choice in the cable industry. Its lightweight nature reduces installation and transportation costs, while its natural corrosion resistance is particularly beneficial in humid or harsh environments.

Aluminum’s recyclability is another major benefit. Aluminum can be recycled indefinitely without losing its performance characteristics, making AAC cables a sustainable option for power transmission networks.

International Standards

AAC cables are manufactured in compliance with various international standards such as IEC (International Electrotechnical Commission), ASTM (American Society for Testing and Materials), and GB (Chinese National Standards). These standards ensure that AAC cables meet the quality and safety requirements for power transmission worldwide. The adherence to these international standards also makes AAC cables highly compatible with electrical grids in different regions, promoting global acceptance.

Applications of AAC Cables

AAC cables are widely used in urban distribution networks and short-distance transmission lines. Their light weight, ease of installation, and relatively low cost make them especially suitable for complex urban environments.

Low and Medium Voltage Power Transmission

AAC cables are commonly used for low and medium-voltage power transmission, particularly in urban and suburban distribution networks. Their design allows for excellent performance over short distances and in moderate environments, such as overhead lines in urban areas. The ease of installation and maintenance makes them a go-to solution for areas with tight spatial constraints.

Overhead Transmission Lines

Due to their low tensile strength, AAC cables are generally used for low-voltage, short-distance overhead transmission lines. They perform particularly well in areas with low wind speeds and minimal mechanical stress, making them a common solution in urban electricity distribution systems. Additionally, because they are lighter, AAC cables require fewer supporting structures, which can result in lower infrastructure costs for electricity providers.

Advantages and Limitations of AAC Cables

Advantages

Excellent Conductivity: Aluminum offers excellent conductivity, enabling AAC cables to efficiently transmit electricity in various energy transmission scenarios. The use of pure aluminum allows for optimal energy flow, reducing energy loss during transmission.

Cost-Effective: The cost of aluminum is significantly lower than that of copper, making AAC cables more economically competitive. For large-scale installations, this price difference can represent substantial savings for energy providers and contractors.

Lightweight: Compared to copper cables, AAC cables are lighter, which simplifies installation and transportation, thus reducing construction costs. This weight advantage makes AAC cables particularly suitable for overhead installations, where minimizing the load on supporting structures is a priority.

Corrosion Resistance: The natural oxide layer formed on the surface of aluminum provides effective protection against corrosion, especially in humid or coastal environments. This increases the lifespan of the cables and reduces the need for frequent maintenance, further lowering the overall cost of ownership.

Limitations

Low Tensile Strength: AAC cables have lower tensile strength than ACSR (Aluminum Conductor Steel Reinforced) ngaahi uaea, making them unsuitable for long distances or environments requiring high mechanical resistance. In regions with strong winds, ice, or other mechanical stress factors, the use of AAC cables may be limited.

Not Suitable for High Voltage Lines: AAC cables cannot withstand the high mechanical pressures in high and extra-high voltage transmission systems. In these cases, more robust cable types such as ACSR are typically used due to their reinforced construction.

Comparison of AAC Cables with Other Cable Types

AAC vs. AAAC (All Aluminum Alloy Conductor)

AAC cables outperform AAAC cables in terms of conductivity and cost. However, AAAC cables, made from aluminum alloy, offer higher tensile strength, making them more suitable for complex transmission lines. The aluminum alloys used in AAAC cables provide increased durability and mechanical strength but at a higher cost than AAC cables.

AAC vs. ACSR (Aluminum Conductor Steel Reinforced)

ACSR cables, reinforced with a steel core, have much higher tensile strength than AAC cables, making them ideal for long-distance transmission. However, AAC cables are more cost-effective for short-distance applications due to their better conductivity and lower cost. ACSR cables are also more resistant to mechanical stress, making them more suitable for areas with adverse environmental conditions such as high winds or heavy snow.

AAC vs. Copper Cables

Copper cables provide superior conductivity and tensile strength compared to AAC cables. However, copper is more expensive and heavier, making AAC cables more economical and practical in many applications. For voltage maʻolunga, long-distance transmissions, copper may be preferred, but for low-voltage, short-distance applications, AAC cables offer a more cost-effective solution.

Future Trends and Development Prospects of AAC Cables

Research on New Materials

With advances in material technology, research is ongoing to improve the mechanical performance and durability of AAC cables. Innovative materials, such as nanomaterials, could enhance the tensile strength of cables while extending their longevity. These advancements would allow for wider use of AAC cables in high-load conditions and extreme environments. The development of composite materials that combine the best properties of aluminum with other metals or compounds could lead to the next generation of AAC cables, further increasing their application potential.

Growing Market Demand

The construction of electrical infrastructure worldwide, particularly in emerging markets such as India, China, and Africa, is expected to drive demand for AAC cables. These countries are developing large-scale electrical infrastructures, and AAC cables, due to their low cost, efficiency, and ease of production, are becoming a preferred solution.

Energy Efficiency and Sustainability

AAC cables are also favored for their environmental sustainability. Aluminum is 100% recyclable, and the production of aluminum cables requires significantly less energy than copper cables. Additionally, recycled aluminum requires only 5% of the energy needed to produce new aluminum, helping to reduce CO2 emissions. This makes AAC cables a preferred solution in sustainability initiatives.

Smart Grids and Automation

With the development of smart grids, AAC cables could play a key role in integrating sensors to monitor real-time temperature, electrical load, and other parameters. This automation would enhance energy distribution management and reduce losses. The incorporation of smart technology into AAC cables can lead to more efficient and responsive power grids, ultimately reducing energy waste and improving the reliability of power delivery.

Fakaʻosi

AAC cables stand out for their excellent conductivity, ola lelei ʻo e fakamolé, lightweight nature, mo corrosion fakafepaki, making them indispensable for short-distance power transmission. While they have limitations in terms of mechanical strength and applicability in high-voltage systems, their use remains strong in many contexts. Technological advancements and a focus on sustainability are expected to further boost their popularity in the years to come. By gaining a deeper understanding of the characteristics and applications of AAC cables, one can appreciate their crucial role in the energy industry and anticipate their growing importance in the development of electrical infrastructure.

In conclusion, AAC cables are a valuable and reliable choice in power transmission. They provide a sustainable, cost-efficient solution for the growing demand for electricity infrastructure worldwide. As the industry continues to innovate and evolve, AAC cables will remain at the forefront of power distribution systems, contributing to a more connected and energy-efficient future.