Bare Conductor — Overhead Cables

The overhead cables produced by ZMS Cable company are of high-quality and low price, and various inspection certificates are available. You can find all kinds of overhead cables in ZMS Cable company. We can produce all of them, and customers who buy our products are all over the world. You can buy with confidence. We specialize in high-quality AAC cables, AAAC cables, ACSR cables, ACAR cables, etc., and other bare conductor overhead cables (ACCC, HTLS Conductor Products, etc.)

Definition of Overhead Cable

The full name of overhead cable is overhead insulated cable. And it is a wire erected in the air and equipped with an insulating layer and an outer sheath. It is different from the overhead power lines Và underground cables. Although, its safety and the degree of optimization of the city’s aesthetics are not as good as underground cables. But it is convenient to erect. And has low maintenance and construction costs. It is widely used in remote areas with a small population base.

Precautions When Laying Overhead Cable

First, erection and installation require professional construction personnel. Although the overhead line is easy to erect, it is based on the professional operation. Only professional construction personnel can operate it, and there will be no hidden dangers after the subsequent installation is completed.

Secondly, the construction rhythm needs to be controlled in place to ensure that the cables will not be damaged during installation.

Thirdly, pay attention to the position of the head: Before construction, be sure to carefully check whether the head is completely sealed.

Advantages of Overhead Cable

First of all, high power supply safety. The safety of the wire is greatly improved compared with overhead wires due to the insulating layer and sheath layer on the outside of the wire. As long as there is no breakdown of this kind of cable, even if a person or animal accidentally touches the cable’s insulation, it will not cause an electric shock accident.

Secondly, high reliability of power supply. Compared with overhead bare conductors, overhead cables have greatly reduced short-circuit accidents and other failures of power supply caused by other reasons.

Thirdly, convenient erection and maintenance. The overhead cable erection is simple and easy. It can be erected not only on the pole frame, but also on the wall, and even on the branches in the woods. Just fix the fittings on the branches.

Fourth, low cost. Although the production cost of overhead cables is higher than that of overhead bare wires, it is much lower than that of underground cables. In addition, due to its ease of erection, its construction cost is also very low.

Types of Bare Conductor Overhead Lines

Overhead cable is a kind of special cable. And its production process is similar to cross-linked cables. Overhead cables can be divided into the following types according to their structure

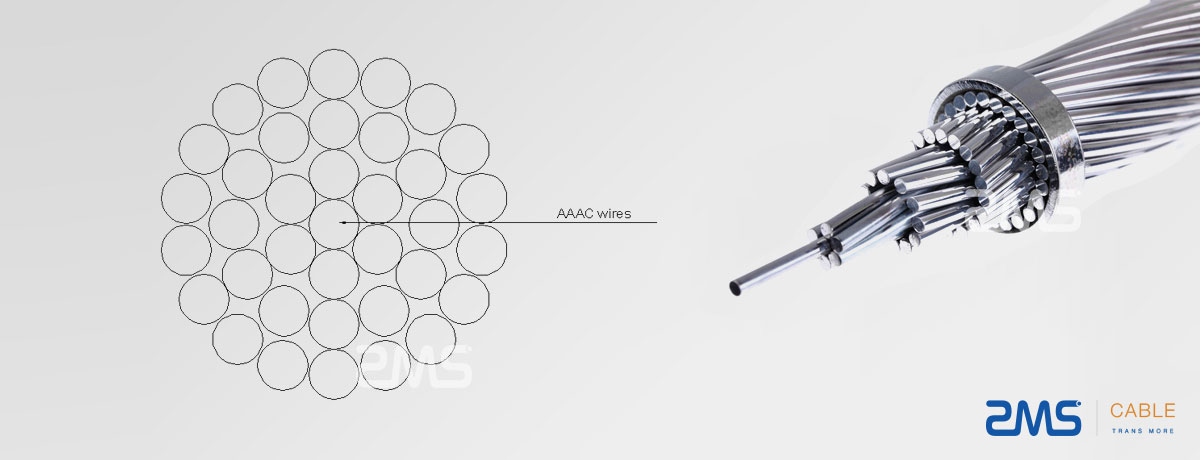

Duralumin wire structure aerial cable (AAC): features light weight, average pulling force, low cost and easy installation.

Overhead cable with hard drawn copper wire structure: heavier quality, large tensile force, and good resistance to external forces.

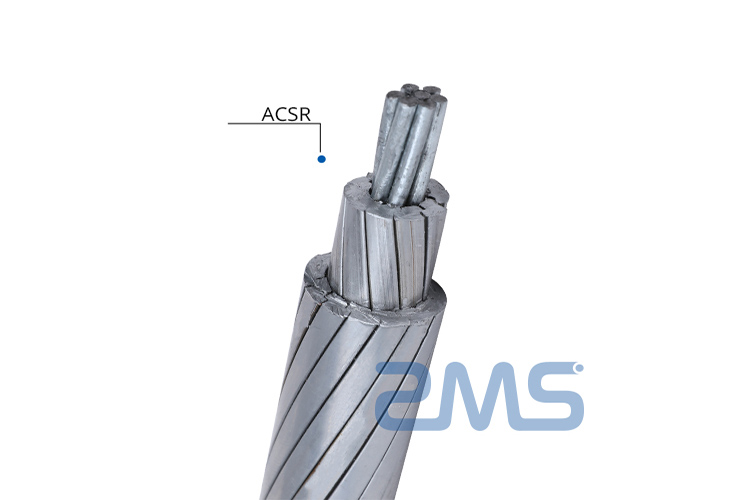

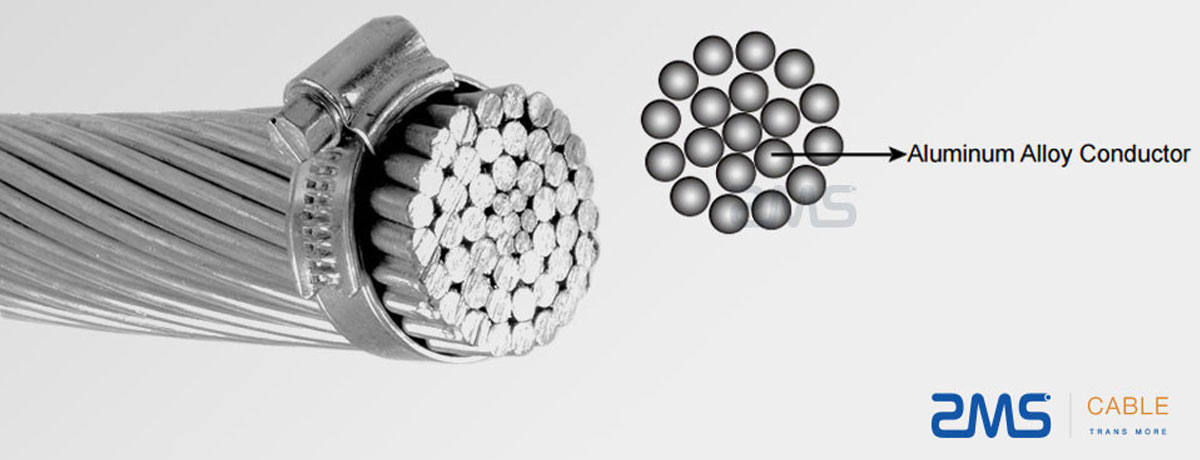

Steel core or aluminum alloy core supporting structure overhead cable (ACSR/ACAR): The sag is small, and the supporting wire can play a role in lightning protection.

Self-supporting three-core twisted structure: suitable for mid-span power transmission systems.

Characteristics of Bare Conductor Overhead Lines

First of all, Rated voltage: 0.6/1KV, 10KV

Secondly, the long-term allowable working temperature of the cable: 70℃ for PVC insulation and 90℃ for XLPE insulation

Thirdly, maximum short-circuit temperature: 160°C for PVC insulation, 250°C for XLPE insulation, 150°C for PE insulation

Fourth, cables cannot be laid when the ambient temperature is lower than 20℃

Fifth, cable bending radius: For low-voltage overhead cables, the bending radius should not be less than 4D if the cable outer diameter is less than 25mm, and the bending radius should not be greater than 6D if the outer diameter is greater than 25mm.

The cable bending radius of medium and high voltage cables should not be less than 20 (D+ d)

About ZMS Cable

ZMS company can produce overhead cables of various specifications and models. You can find the model cable you want here, if you don’t find it, you can also contact our customer service staff. The cables we provide are all certified by the inspection certificate. The quality is guaranteed, and we are the leader in the same industry in terms of price and transportation.